STEELFAB has the LARGEST group of steel processing equipment in Alaska.

- Messer MPC2000 – Largest burn table in the state

- Prodevco PCR42 – Only beam line in the state

- Ogden Dart 1V – Only beam fabricator in the state

- Masteel-MBHS20600 – Largest press brake in the state

STEELFAB has the equipment to process steel plates, angles, beams, tubes, channels, and pipes of just about any size and shape. If your WF beam size is not a standard size, we can custom fabricate to your specification in our 83,000-square-foot shop. For completing projects, STEELFAB will comply with your AISC/Project specifications.

Processing

Equipment

- Messer MPC2000 Precision Cutting System

- Messer Titan II Plasma Cutter

- Prodevco PCR42 Robotic Plasma Thermal Cutter

- Ogden Dart IV Beam Fabrication

- MASTEEL MBHS-20600 Press Brake

- Accurpress 725012 Press Brake

- Bertsch: #14 Plate Roller

- IMCAR CPHV80 Pipe Roller

- HTC 500-10A Shear

- Spartan Model IW 180-DX Ironworker

- Kalamazoo Hot Saw

- Trennjaeger Cold Saw

- HEM Saw WF 130 HA-DC-C

- HEM Saw VT 120 HA

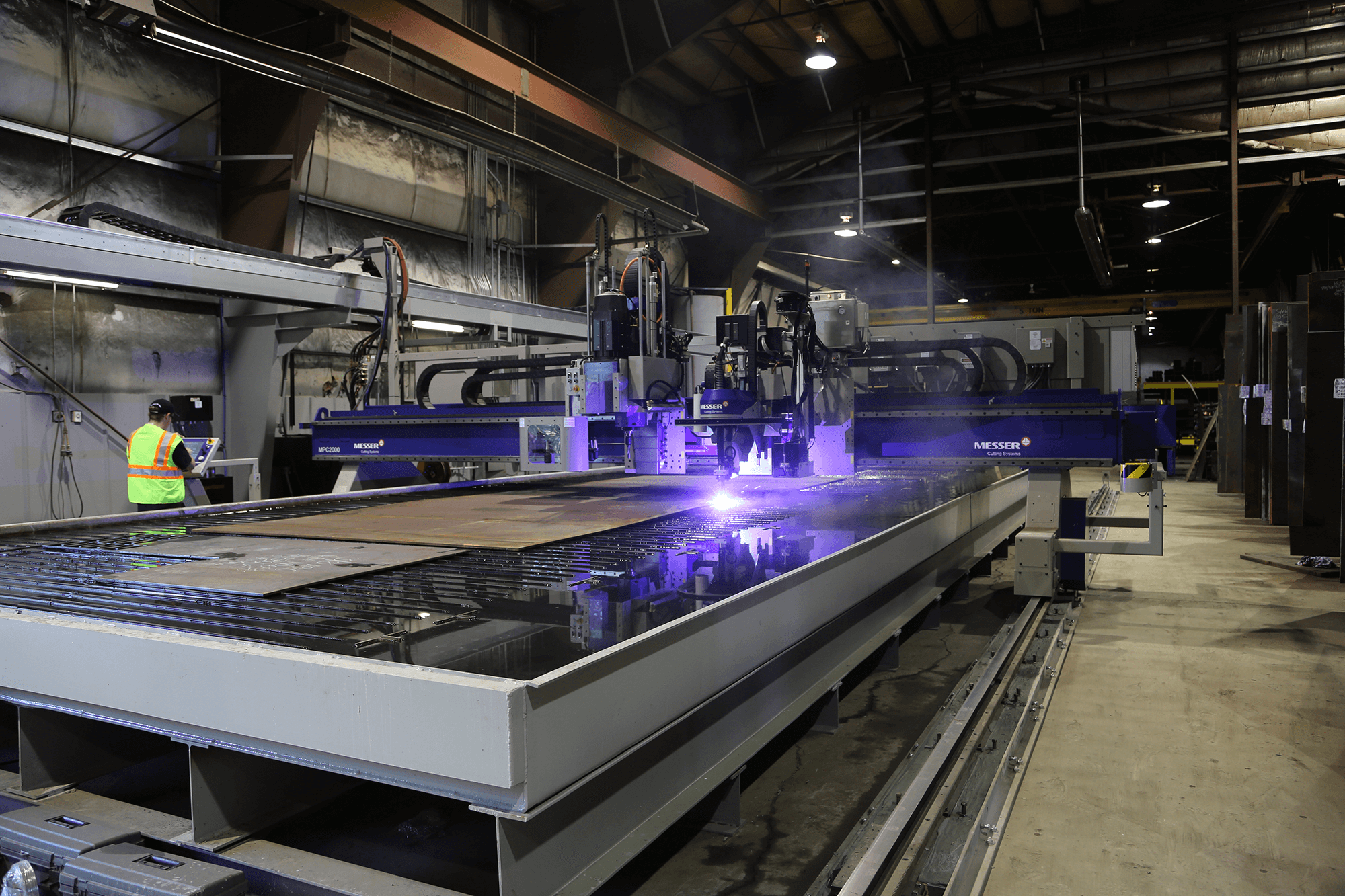

Messer MPC2000 Precision Cutting System

- LARGEST plate processing machine in Alaska at 17′ wide x 55′ long

- Powered by Hypertherm HPR400XD – HD Plasma Cutting System

- Capable of processing steel sheets up to 2″ thick

- Burn any shape holes including round, square, obround, etc

- Multiple bevel capabilities

- Built-in drill line, with available bit sizes up to 2″

- Rip WT shapes from wide flange beams up to 50′ long

- Perforate pipe, angle, square, and rectangle tube

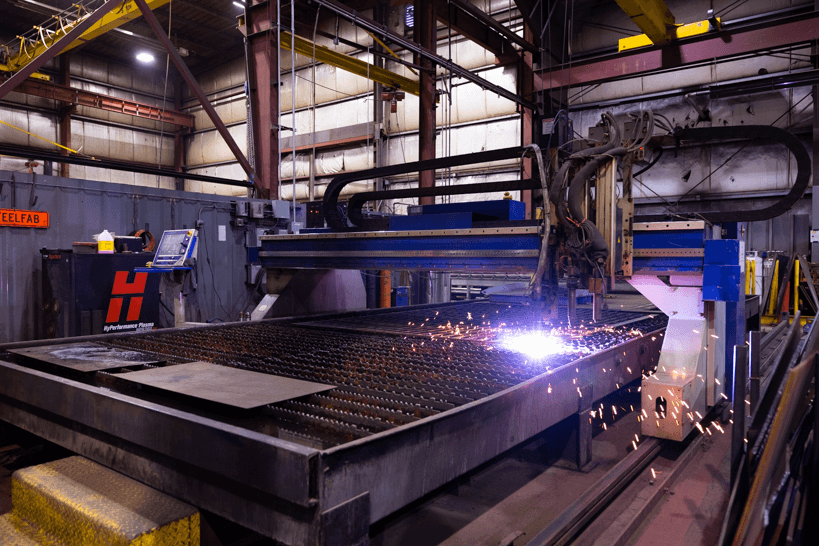

Messer Titan II Plasma Cutter

- 10′ wide x 24′ long

- Powered by a Hypertherm HPR260XD, capable of processing 1.5″ thick plate

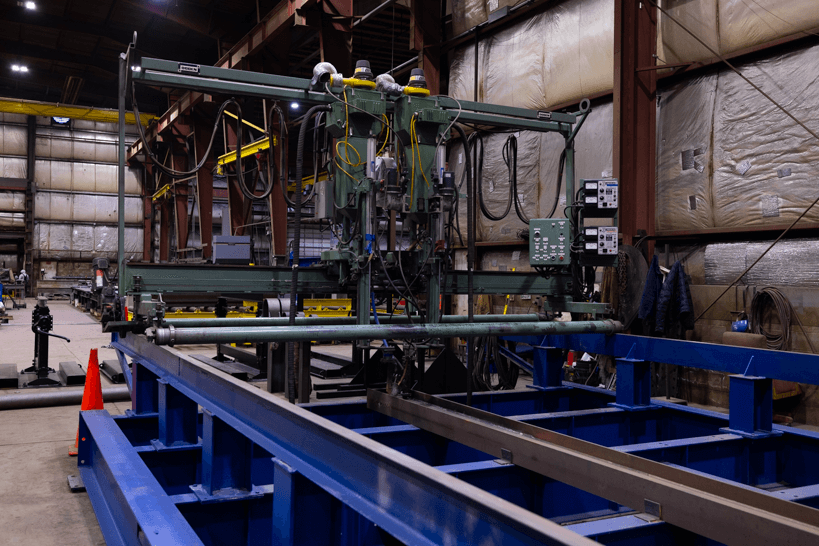

Prodevco PCR42 Robotic Plasma Thermal Cutter

- ONLY beam line in Alaska

- Powered by a Hypertherm XPR300 HD Plasma Cutting System

- Includes a robotic arm for precision and power

- Capable of cutting four faces of a profile in a single pass including slots, holes, copes, and markings

| Shape | Minimum (in) | Maximum (in) | ||

| Width | Height | Width | Height | |

| H Beam | 4 | 4 | 36 | 16 |

| Channel | 3 | 1.25 | 36 | 16 |

| Angle | 2 | 2 | 8 | 8 |

| HSS | 2 | 2 | 24 | 20 |

| Round* | 4 | 4 | 26 | 26 |

| Minimum raw shape length is 7’ X unlimited max length *Requires round tube/pipe option (hollow sections) |

||||

Ogden Dart IV Beam Fabrication

- ONLY adjustable beam welding system in Alaska

- STEELFAB is the only processor with the ability to custom fabricate low temp (CVN tested) structural steel shapes that meet arctic environment specifications

- This system supplies high-quality welds at speeds six times the manual rate, with the ability to make custom size and length beams to exacting specifications

- Minimum 10″ between flanges and a maximum 120″ between flanges

- Necessary equipment for AISC Bridge Fabricating Certification

Masteel MBHS 20600 Press Brake

- LARGEST press brake in Alaska

- 600-ton press brake

- Capable of bending .5” thick x 20’ long plate into a 90-degree angle

Accurpress 725012 Press Brake

- 250-ton press break

- Capable of bending steel plate up to .25″ thick x 12ft long

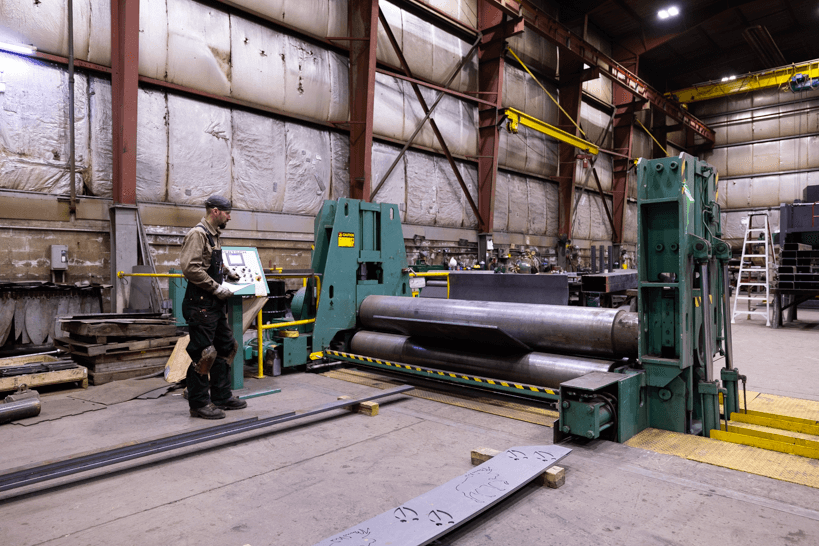

Bertsch #14 Plate Roller

- LARGEST capacity plate roller in Alaska

- Capable of rolling steel plate up to 1” thick x 10’ wide

Spartan Model 180-DX Ironworker

- Reliable and durable punch and shear station for high-quality metalwork

- 180-ton capacity

Kalamazoo Hot Saw

- Capable of cutting tube, angle, flat and round bar, and channels

- Used for all warehouse applications

Trennjaeger Cold Saw

- Precision cutting of all materials including aluminum, steel, alloys, and stainless

- Capable of cutting steel plates up to 5″ thick and 39″ wide

- Bar grate cutting

HEM Saw WF 130 HA-DC-C

- 1.5″ blade driven by an lOHP motor

- 48″ bar-feed offers multiple indexes for longer parts